PCB制造设计用系统

新制造设计专用通用平台

DFM Center依靠最新PCB板设计/制造设计的自动功能、对各种制造/测试装置的CAM输出,实现最佳DFM/DFT环境。 不仅支持图研的格式,而且还支持业界的所有格式。

支持所有制造设计过程的功能与概念

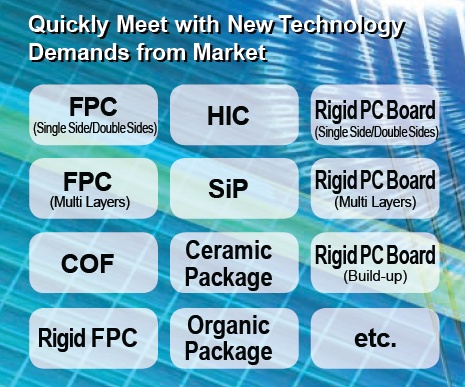

DFM Center是新一代制造设计环境,对于刚性/封装/FPC板等所有领域,配备了完善的功能。

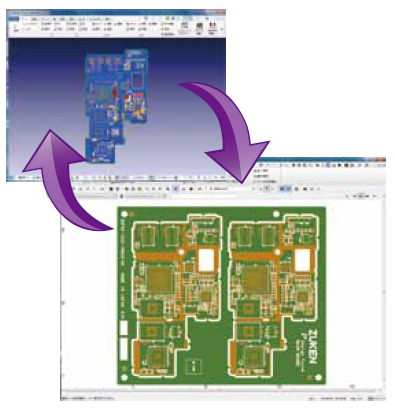

凭借丰富的布线图功能提高校验功能、与PCB设计紧密协作,提高设计效率。

【参照图像:专业性和专用性的高度追求】

制造设计的过程因PCB板类别而异,所需的功能与技术一起不断发展。从数据输入到数据清除的各种编辑功能、

每项PCB板技术的校验功能、工卡模具的设计、图纸绘制、各种制造装置专用格式的输出等,提供丰富多彩的强大功能。

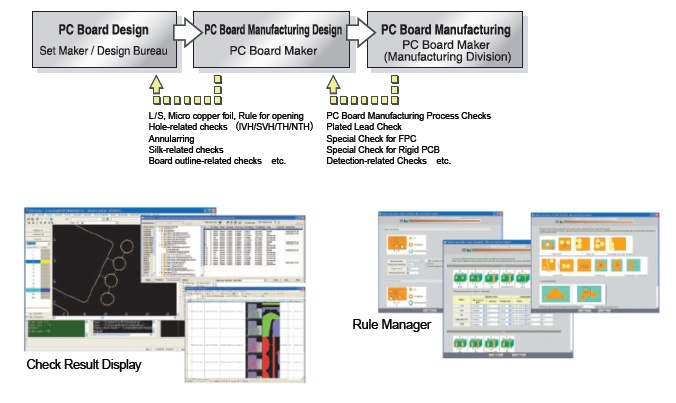

【参照图像:提供制造设计和制造验证两种解决方案】

PCB Design System for Manufacturing

A New Universal Platform for Manufacturing Design

Through its CAM output functions to a variety of manufacturing devices and test devices, and its many automatic functions improving the efficiency of panel design and manufacturing design incorporating the latest board technologies, DFM Center provides an optimum DFM/DFT environment. It is compatible not only with Zuken formats, but also with most standard industry formats.

Specialized functions compatible with most manufacturing design processes and universal concepts

DFM Center is a next generation manufacturing design environment fully equipped with specialized functions

for working with all regions of rigid, package and FPC boards. With its full range of artwork functions indispensable

for manufacturing design, highly specialized check functions for all areas, and tight integration with board design

systems, it provides more efficient manufacturing design.

(Reference picture: Working towards Increased Specialization and Specialized Use)

Manufacturing design processes are largely different for each type of board, and the functions required are evolving

together with technology. In accordance with such facts, DFM Center offers a wide range of powerful functions,

from data import to data cleanup, all necessary editing functions, check functions for different board technologies,

as well as tool design, diagram drafting and data output in formats for use with a variety of manufacturing devices.

(Reference picture : Offering Solutions for Both Manufacturing Design and Verification)